The Role of Precision Resistors in Industrial Power Monitoring and Smart Grid Systems

- laifutechco

- Jul 28

- 5 min read

In today's fast-paced, energy-driven world, industrial power monitoring and smart grid systems play a pivotal role in ensuring efficiency, safety, and sustainability. At the heart of these systems lies a small but mighty component: the precision resistor. These components are essential for accurate current measurement and voltage regulation. If you're a system designer, engineer, or procurement specialist searching for a reliable shunt resistors manufacturer, understanding the role of precision resistors is key to building robust and reliable electrical systems.

Understanding Precision Resistors: What Makes Them Different?

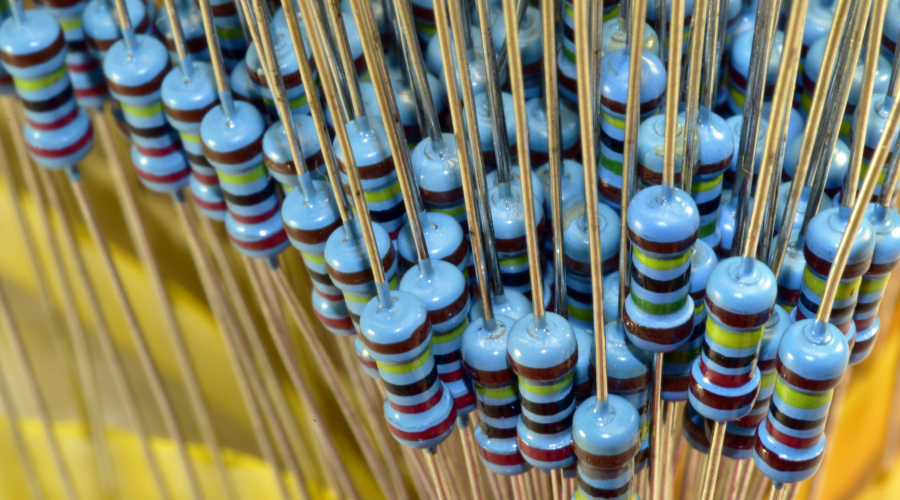

Unlike general-purpose resistors, precision resistors are designed for high accuracy, tight tolerance, and low temperature coefficient. These properties allow them to maintain a consistent resistance value even under changing temperatures and electrical loads.

Key features include:

Tolerance levels as tight as ±0.01%

Temperature Coefficient of Resistance (TCR) as low as ±1 ppm/°C

Long-term stability over years of usage

Low thermal EMF (Electromotive Force)

These features make precision resistors indispensable in applications where even a minor variation can lead to incorrect readings or system failure.

The Role of Precision Resistors in Industrial Power Monitoring

1. Accurate Current Measurement

In industrial environments, monitoring current flow is crucial for load balancing, efficiency optimization, and fault detection. Precision resistors, particularly in the form of shunt resistors, are used to measure current indirectly.

When electrical current passes through the resistor, it creates a small voltage drop, which is then measured and used to calculate the current. This method requires ultra-precise resistance values to ensure accuracy, which only high-grade precision resistors can offer.

2. Voltage Regulation

In power monitoring systems, stable voltage is critical. Variations can damage sensitive equipment or lead to process interruptions. Precision resistors are used in voltage dividers and reference circuits, helping regulate and stabilize voltage levels throughout the system.

Precision Resistors and the Smart Grid Evolution

As energy demand grows, so does the need for intelligent energy distribution. Smart grid systems rely heavily on real-time data collection, communication, and automation to manage power flow efficiently.

Here's how precision resistors help power the future of smart grids:

1. Smart Metering

Smart meters installed in homes and commercial buildings use precision resistors to measure energy consumption with pinpoint accuracy. This data is then transmitted to utility providers for billing and load management.

2. Power Quality Monitoring

Precision resistors assist in monitoring voltage sags, surges, and harmonic distortions. Their consistent resistance ensures that these fluctuations are accurately detected and corrected.

3. Grid Load Balancing

To prevent overload and ensure fair distribution, grid operators need real-time data. Precision resistors in measurement circuits provide high-fidelity data, allowing for smarter decisions regarding power routing.

Applications Across Industrial Sectors

Precision resistors aren't limited to just one industry. Their use spans multiple sectors, including:

Renewable Energy Systems – Solar inverters and wind turbines rely on precision resistors for real-time power conversion monitoring.

Automotive Industry – Electric vehicles (EVs) use them for battery management systems (BMS), monitoring charge/discharge cycles with exact measurements.

Medical Devices – Instruments like MRI machines or defibrillators require stable, precise resistance values to operate safely.

Aerospace and Defense – In avionics and control systems, precision resistors ensure mission-critical reliability.

Why Choosing the Right Shunt Resistors Manufacturer Matters

Not all precision resistors are created equal. The quality, reliability, and performance consistency depend significantly on the capabilities of the shunt resistors manufacturer you partner with. Here's what to look for when selecting a supplier:

Traceability and Certifications – Look for ISO 9001, RoHS, and REACH compliance.

Material Quality – Nickel-chromium alloys or manganin materials for minimal drift.

Customization Options – Need non-standard resistance values or form factors? Choose a vendor who offers custom solutions.

Environmental Testing – Ensure resistors can withstand thermal cycling, vibration, and humidity.

Support and Expertise – A knowledgeable supplier can guide you toward the best-fit resistor for your unique application.

Precision Resistors vs. Standard Resistors: What's the Difference?

FeaturePrecision ResistorsStandard Resistors

Tolerance ±0.01% to ±0.1% ±1% to ±10%

Temperature Coefficient ±1 to ±25 ppm/°C ±100 to ±500 ppm/°C

Stability Over Time Excellent Average

Use Case Measurement & Calibration General Applications

Price Higher Lower

While standard resistors are perfect for general circuits, precision resistors are indispensable

where measurement accuracy, stability, and control are non-negotiable.

Emerging Trends in Precision Resistor Technology

As technological progress, so do the demands placed on resistor performance. Here are a few trends shaping the future:

Miniaturization – Smaller, high-performance resistors to fit compact PCBs in IoT and wearable devices.

Automated Calibration – Integration with smart calibration tools for plug-and-play applications.

High-Power Precision Resistors – Designed for high-voltage environments like power substations and electric trains.

Environmental Resilience – Resistors built to survive extreme temperatures and corrosive environments.

Tips for Integrating Precision Resistors in Your Design

If you're an engineer or system designer, here are practical tips to optimize your power monitoring setup with precision resistors:

Consider TCR in Your Calculations – Even small temperature changes can affect resistance.

Avoid Thermal Hotspots – Place resistors away from heat-sensitive components.

Use 4-Terminal (Kelvin) Connections – This minimizes lead resistance error.

Simulate First – Use SPICE or equivalent tools to model real-world behavior before prototyping.

Conclusion:

Precision resistors may be small, but their impact is massive—especially in industrial power monitoring and smart grid systems. Whether it's ensuring accurate current readings, stabilizing voltage, or enabling efficient energy management, these components are foundational to modern electrical infrastructure.

Partnering with a reliable shunt resistors manufacturer ensures you get not only consistent quality but also the engineering support needed to meet demanding industrial and smart grid requirements. As the world moves toward smarter, more sustainable energy systems, the demand for high-quality precision resistors will only continue to grow.

FAQs

Q1: What is the main purpose of a precision resistor?

A: Precision resistors are designed to provide extremely accurate and stable resistance, often used in measurement circuits, voltage regulators, and power monitoring systems.

Q2: How does a shunt resistor work in power monitoring?

A: A shunt resistor creates a voltage drop proportional to the current passing through it. This voltage drop is then measured to calculate the current flow in the circuit.

Q3: Why is TCR important in precision resistors?

A: TCR (Temperature Coefficient of Resistance) indicates how much a resistor's value changes with temperature. Lower TCR means better accuracy under varying thermal conditions.

Q4: Can I use standard resistors in place of precision resistors?

A: Not in critical applications. Standard resistors have looser tolerances and may drift over time, which can compromise the accuracy of your system.

Q5: What elements should I consider when choosing a shunt resistors manufacturer?

A: Look for quality certifications, resistance stability, low TCR, material quality, and support for customization and technical guidance.

Comments